What is Laser Engraving? Its Types and Applications

Laser engraving has revolutionized the way we mark, decorate, and design materials. Unlike traditional manual engraving, which requires skill and time, laser engraving is a fast, accurate, and versatile technology. From intricate patterns on jewelry to precise barcodes on industrial components, laser engraving offers an efficient and modern solution for a wide range of applications.

But what exactly is laser engraving? Let’s explore its essence, types, and their applications in detail.

What is Laser Engraving?

Laser engraving is a method that uses a focused laser beam to remove material from the surface of an object. This subtractive manufacturing process creates a permanent mark, leaving behind sharp, detailed designs. By vaporizing the surface, laser engraving can be used to inscribe logos, text, images, or textures onto various materials such as wood, metal, glass, and plastics.

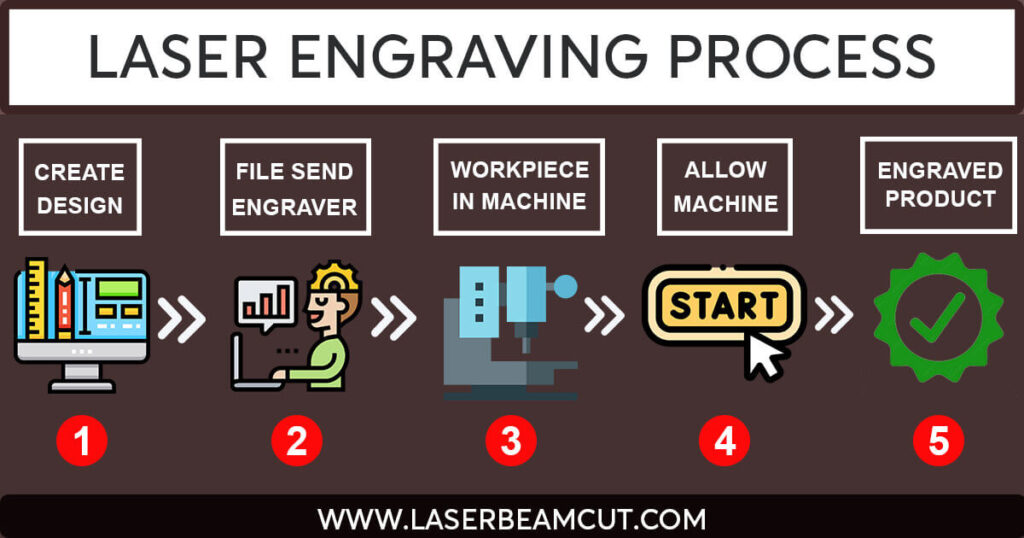

The process begins with designing the pattern or image using specialized software, then sending that design to the laser engraving machine, which engraves the object according to the digital blueprint. This technology is precise, making it ideal for small, intricate designs that would be challenging with traditional methods.

Comparison with traditional Engraving

Traditional engraving methods, like hand engraving, rely on manual tools and the skill of a craftsman to etch designs into various materials. This approach allows for a personal touch and unique artistry, but it can be time-consuming, labor-intensive, and requires a high level of expertise. Additionally, traditional methods are limited in precision, making it challenging to create intricate or complex patterns, especially on small or delicate items like jewelry.

In contrast, laser engraving uses focused laser beams to remove material, offering unmatched accuracy and efficiency. Unlike traditional methods, laser engraving can produce detailed, consistent designs quickly and is ideal for mass production, ensuring each item is identical. It also works on a broader range of materials—from metals and plastics to wood and glass—making it more versatile. This technology has largely replaced manual engraving due to its speed, precision, and ability to handle complex patterns with ease, reducing both costs and production time.

Why Choose Laser Engraving?

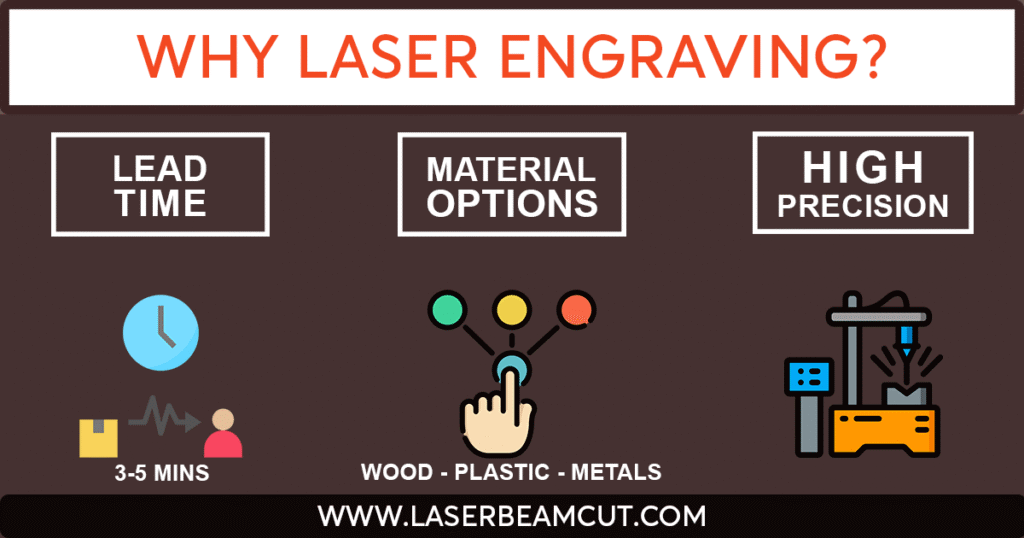

Laser engraving offers several advantages over manual engraving:

- Speed and Efficiency: Every laser pulse removes material, completing detailed engravings within seconds.

- Versatility: Suitable for a wide variety of materials, including metal, wood, leather, and glass.

- Precision: Laser engravers provide sharp and accurate designs, perfect for fine details and complex patterns.

- Consistency: Ideal for mass production, ensuring each product looks identical to the next.

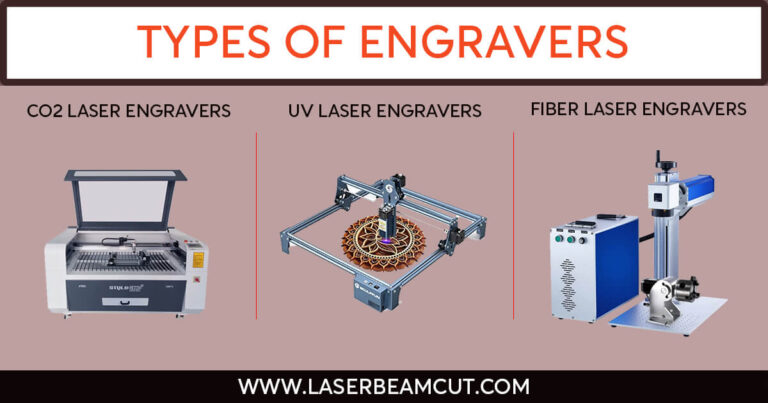

Types of Laser Engraving

Laser engraving can be categorized into several distinct types, each serving different purposes and delivering unique results based on the desired outcome and material used. Here are the primary types of laser engraving:

1. Surface Engraving

Surface engraving is the most common form of laser engraving, involving the removal of the material’s surface layer to create a design. It results in shallow, precise marks that are visible without deep cuts. Surface engraving is ideal for creating logos, text, patterns, and detailed artwork on various materials like wood, plastic, and glass. This method is often used for aesthetic purposes, like creating personalized items or decorative designs.

2. Deep Engraving

Deep engraving uses a higher laser power to remove more material, creating deeper cuts into the surface. This type of engraving is common in industrial applications where durability and permanence are crucial, such as marking machine parts, tools, and heavy-duty equipment. Deep engraving is often used on metals like steel and aluminum to ensure that markings remain legible, even under harsh conditions.

3. 3D Laser Engraving

3D laser engraving adds depth and dimension to designs, allowing for the creation of three-dimensional effects. This technique involves varying the intensity and depth of the laser to produce realistic textures and contours. 3D engraving is particularly popular in the art and jewelry industries for creating intricate designs that appear to stand out from the surface, providing a unique, high-quality finish.

4. Laser Etching

Laser etching is a type of engraving that melts the surface of the material, creating a raised mark. It uses lower power compared to other forms of laser engraving and is typically faster. Laser etching is particularly useful for marking plastics, ceramics, and metals with a contrasting mark, making it ideal for barcodes, logos, and identification numbers that need to stand out visually. It’s a suitable choice for products requiring quick, permanent marks without deep cuts.

5. Laser Ablation

Laser ablation involves removing the top layer of a coated material to reveal a contrasting layer beneath. This method is frequently used on materials like anodized aluminum or painted metals. It’s a highly effective way to create high-contrast designs, making it perfect for producing detailed labels, nameplates, and control panels. Laser ablation is known for its precision and clarity, even on small or intricate designs.

6. Inside or Subsurface Engraving

Subsurface engraving targets the inside layers of transparent materials like glass or acrylic, without affecting the outer surface. The laser beam focuses beneath the surface, creating small fractures within the material that form a pattern or image. This type of engraving is excellent for creating 3D images inside crystal or glass, often used in awards, decorations, and personalized gifts.

7. Laser Marking

Although technically distinct from engraving, laser marking is often grouped under the same category. It uses a lower-powered laser to discolor the surface of the material without removing it, creating marks by oxidizing or heating the surface. Laser marking is primarily used for identification marks, barcodes, logos, and serial numbers. It’s a preferred method in industries requiring non-invasive and high-contrast labeling.

Each type of laser engraving has its own unique strengths, making it crucial to choose the right method based on the material, application, and desired outcome.

Applications of Laser Engraving

Laser engraving is a versatile technology with applications spanning across various industries, thanks to its precision, speed, and ability to work on a wide range of materials. Below are some of the most common applications:

1. Jewelry and Personalization

Laser engraving is widely used in the jewelry industry for creating intricate designs, patterns, and inscriptions on rings, necklaces, and watches. It allows for fine detailing on small surfaces, making it ideal for customizing jewelry with names, dates, and unique patterns, adding a personal touch to gifts and special items.

2. Industrial Marking and Traceability

In manufacturing, laser engraving is essential for marking parts with barcodes, serial numbers, and logos for traceability. These permanent marks are crucial for tracking inventory, ensuring quality control, and maintaining product authenticity. The automotive, aerospace, and electronics industries heavily rely on laser engraving for precise part identification.

3. Awards and Trophies

Laser engraving is popular for creating clean, detailed engravings on awards, trophies, and plaques. It allows businesses to produce customized awards with logos, text, and designs, giving them a professional and polished look that lasts for years.

4. Medical and Scientific Instruments

The medical industry uses laser engraving to mark medical devices and instruments with critical information like serial numbers, scales, or measurements. These permanent, sterile marks ensure compliance with safety standards and make it easy to identify and track equipment in the healthcare environment.

5. Electronics and Circuit Boards

Laser engraving is employed in the electronics sector to mark circuit boards and electronic components with part numbers, logos, and codes. It ensures high accuracy without damaging delicate electronic parts, making it a preferred method in the tech industry for labeling and identification.

6. Signage and Decorative Items

Businesses use laser engraving to create custom signs, labels, and decorative items. The precision of laser engraving allows for detailed logos, intricate designs, and readable text, making it perfect for creating professional signage, plaques, and personalized decor.

7. Leather Goods and Textiles

Laser engraving is also used in the fashion industry to add unique textures and designs to leather goods like wallets, belts, and bags. It can create intricate patterns and logos on fabric, offering a sophisticated way to personalize and brand clothing, accessories, and other fashion items.

8. Prototyping and Art

Designers and artists utilize laser engraving for creating prototypes and detailed artwork. It enables rapid development of models with precise details, allowing for easy modifications and iterations. Artists also use it to create intricate engravings on various mediums, including wood, metal, and glass, giving a modern twist to traditional art forms.

9. Architectural Models

In architecture, laser engraving is employed to create detailed architectural models and blueprints. The technology’s precision enables accurate representation of designs, making it easier to visualize and present construction projects to clients and stakeholders.

10. Customized Gifts and Promotional Items

Laser engraving is frequently used for personalizing gifts, awards, and promotional items. From engraved pens and keychains to customized tumblers and phone cases, it allows for branding and unique personalization, making ordinary items feel special and distinctive.

Laser engraving has become a cornerstone technology in diverse industries due to its ability to deliver precise, durable, and high-quality results, making it an invaluable tool in modern production and design.

Final Words

Laser engraving has become a game-changer in modern design and manufacturing, offering unmatched precision, speed, and versatility across various applications. From personalized gifts to industrial marking, it continues to replace traditional methods with efficiency and accuracy. As technology evolves, laser engraving remains an essential tool, bringing creativity and functionality together in one powerful process.

2 Comments